- Mill Drill Milling

- Brand

- Ad International (9)

- Bridgeport (22)

- China (5)

- Cleveland (28)

- Emco (9)

- Evermore (6)

- Grizzly (11)

- Haas (23)

- Haywhnkn® (16)

- Intbuying (34)

- Intbuying® (10)

- Jet (80)

- Michigan Drill Corp. (9)

- Micro 100 (20)

- Monster Tool Company (8)

- Preasion (5)

- Preasion® (11)

- Precision Matthews (12)

- Shdiatool (6)

- Techtongda (32)

- ... (1003)

- End Type

- Feature 2

- Material

- Overall Size

- Speed

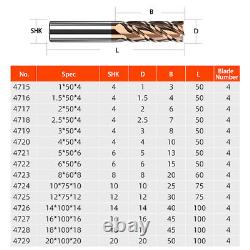

4-Flute End Mill Bits Tungsten Carbide CNC Shank Drill Bits Cutter For Steel

4-Flute End Mill Bits Tungsten Carbide CNC Shank Drill Bits Cutter For Steel. 15 Kinds of Specifications, 4 Kinds of Hardness, There Is Always One to Meet Your Needs. Product Name: Four Flute Solid Carbide Spiral Router Bit CNC End Mill Cutte.

Number of blades: 4 Flute. Applicable Materials: Stainless Steel Cast Iron Tool Steel Alloy Steel Graphite Plastic Composite Materials, Etc.Applicable Machines: CNC Machining Centers, Engraving Machines, Engraving Machines and Other High-speed Machines. Properly Reducing the Cutting Speed and Feed Speed Can Prolong the Service Life of the Milling Cutter. When Working, It Is Necessary to Add Cutting Fluid to Protect the Knife Edge and Make the Cutting Smoother. When There Is an Oxide Film or Other Hardened Layer Remaining on the Surface of the Workpiece, It Can Be Removed by Reversible Milling. 55° Four Flute Coated End Mills, Sharp, Sturdy, Fast Milling, v Sharp Edge v Smooth Chip Evacuation v Individually Packed.

TISIN Coating on the Cutting Edge, Tisin Coating Can Directly Perform Rough Machining to Fine Machining on Heat-treated Materials Below 55°, Reduce the Number of Tool Changes, Improve Machine Tool Utilization, and save Manufacturing Time. 06um Micro-grain Tungsten Steel Cemented Carbide Adopts Micro-grain Tungsten Steel Base Material, Which Has Higher Wear Resistance and Strength. It Is an Exclusive Milling Cutter for High-hardness and High-speed Cutting Applications.

The Fully Ground Cutting Edge Is Sharp, Wear-resistant and Durable, Making a Strong Guarantee for the Service Life of the Milling Cutter and Longer Service Life. The Large Core Diameter Is More Stable and the Large Core Diameter Design Is Adopted Under the Condition of the Cutting Space, Which Greatly Enhances the Rigidity and Shock Resistance of the Tool and Reduces the Broken Tool. Four Flute Mainly Side Milling and Face Milling. Large Chip Removal, Full Grinding Spiral Groove, Fine Grinding Spiral Groove, Avoid Sticking Knife, Greatly Improve Production Efficiency. Universal Chamfering, Round Shank Is Easy to Use, Has Good Compatibility, Enhances the Vibration Resistance and Cutting Speed of the Milling Cutter, and the Clamping Is Tighter and Does Not Slip.Description of the Scope of Application Can Be Applied to Metal, Wood, Plate and Other Materials. Instructions for Use What Buyers Need to Know About the Selection and Operation of Knives.

Before Using the Tool, Please Measure the Tool Deflection. When the Tool Deflection Accuracy Exceeds 0.01mm, Please Correct It Before Cutting. The Shorter the Length of the Tool Extension Chuck, the Better. If the Tool Extends Longer, the Speed, Feed Rate or Cutting Amount Should Be Reduced.

During Cutting, If Abnormal Vibration or Sound Occurs, Please Reduce the Speed and Cutting Amount Until the Situation Improves. The Cooling of Steel Is Preferably Spray Type and Jet Type, Which Can Improve the Use Effect of the Milling Cutter. SHK(Shank Size)D(Cutting Diameter)B(Flute Length)L (Overall Length).